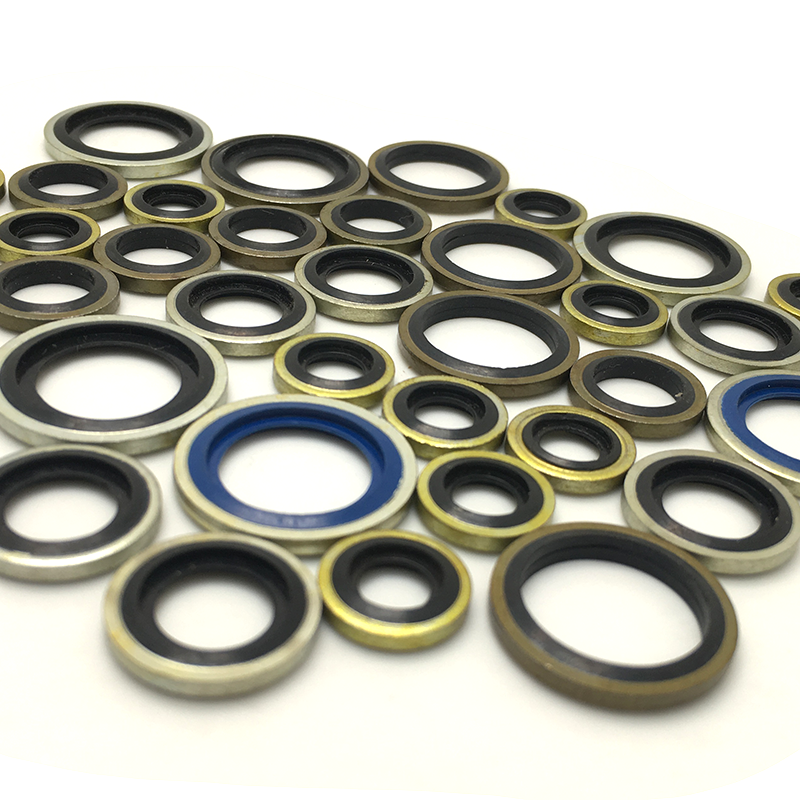

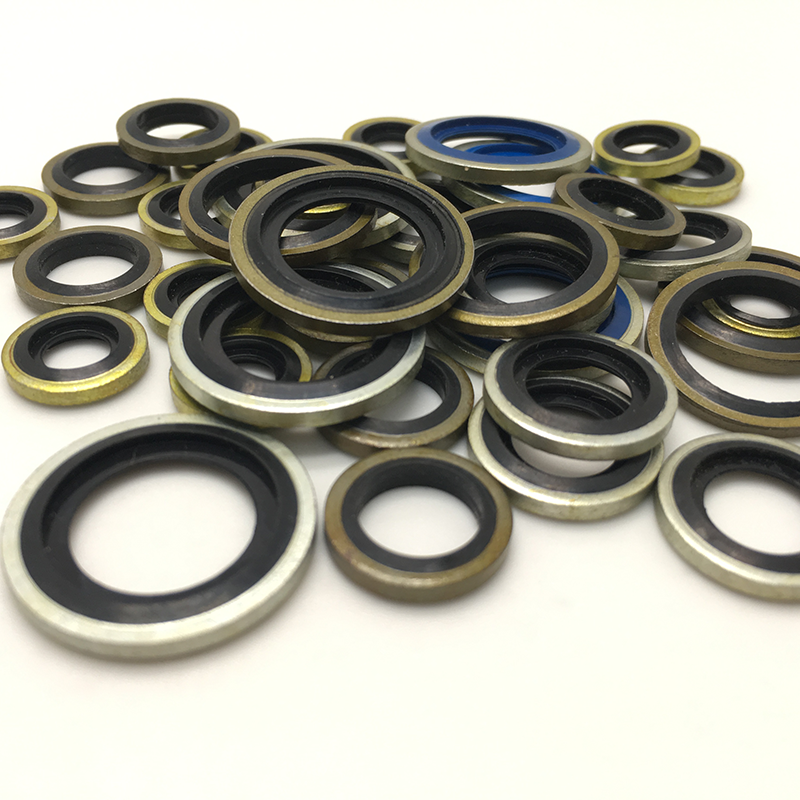

China Manufacture Rubber Metal Bonded Sealing Washer self-centering bonded gasket

Product Description

Bonded gasketThe combined gasket is made of a rubber ring and a metal ring integrally bonded and vulcanized. It is a sealing ring used to seal the thread and flange connection. The ring includes a metal ring and a Rubber Gasket.

Bonded gasketThe combined gasket is made of a rubber ring and a metal ring integrally bonded and vulcanized. It is a sealing ring used to seal the thread and flange connection. The ring includes a metal ring and a Rubber Gasket.Working pressure: ≤40 Mpa Temperature: -25℃ ~ +100℃ Medium: hydraulic oil Material: rubber, metal

It is suitable for the pressure system sealing of oil-based pipeline systems for welding, ferrules, expanded pipe joints, screw plugs and mechanical devices to prevent leakage of oil, fuel, water and medicines. Because of its simple structure, efficient sealing, and low price, it has been widely used in machinery manufacturing.

Type | ID(mm) | Allowed Error(mm) | OD(mm) | Allowed Error(mm) | For Screw |

Φ6 | 6.4 | +0.12 | 12 | +0.12 | M6 |

Φ8 | 8.4 | 14 | M8 | ||

Φ10 | 10.4 | 16 | M10(G1/8'') | ||

Φ12 | 12.4 | 18 | M12 | ||

Φ13 | 13.2 | 20 | +0.15 | NON-STANDARD | |

Φ14 | 14.4 | 20 | M14(G1/4'') | ||

Φ15 | 15.2 | 23 | NON-STANDARD | ||

Φ16 | 16.4 | 23 | M16 | ||

Φ17 | 17.2 | 25 | NON-STANDARD | ||

Φ18 | 18.4 | 25 | M18(G3/8'') | ||

Φ20 | 20.5 | +0.14 | 28 | M20 | |

Φ21 | 21.2 | 30 | NON-STANDARD | ||

Φ22 | 22.5 | 30 | M22(G1/2'') | ||

Φ24 | 24.5 | 32 | +0.2 | M24 | |

Φ26 | 26.5 | 35 | NON-STANDARD | ||

Φ27 | 27.5 | 35 | M27(G3/4'') | ||

Φ30 | 30.5 | 38 | M30 | ||

Φ33 | 33.5 | +0.17 | 42 | M33(G1/4'') | |

Φ36 | 36.6 | 46 | M36 | ||

Φ39 | 39.6 | 50 | M39 | ||

Φ42 | 42.6 | 53 | +0.25 | M42(G1'') | |

Φ45 | 45.6 | 56 | M45 | ||

Φ48 | 48.7 | 60 | M48(G2'') | ||

Φ52 | 52.7 | +0.20 | 66 | M52 | |

Φ60 | 60.7 | 75 | M60 |

Material | Hardness (Shore A) | Temperature | Size | ||

Standard Size | Available | ||||

NBR(Buna, Nitrile) FKM(VlTON, FPM) EPDM Silicone(VMQ) HNBR FFKM(FFKM, Kalrez) AFLAS FVMQ PU CR PTFE | 60~90 70~90 60~90 40~70 60~90 70~90 70~90 70~90 50~90 60~90 60~90 | -40℃-120℃ -20℃-200℃ -50℃-150℃ -70℃-220℃ -40℃-150℃ -18℃-326℃ -2℃-230℃ -60℃-200℃ -40℃-90℃ -40℃-120℃ -100℃-280℃ | ID≤2000mm CS≤40mm | ||

Resistance | Color | Certificate | Application | ||

Hydraulic Fluid Engine Oil Chemical Ozone & UV Steam & Hot Water Low Temperature High Temperature | Black Brown Red Green White Blue Clear Customized | ISO9001 1SO14001 TS16949 RoHS REACH FOOD GRADE CT | Auto Industry Construction Machinery Machine Tool Equipment Food Health Water Treatment Chemical Processing Hydraulic Pneumatic Industrial Manufacturing | ||

10 years of rubber seal products manufacturer

10 years of rubber seal products manufacturer26 years of rubber industry technical experience

More than 5000 sets of molds

Nearly 20,000 seal specifications

High-quality raw materialsExcellent workmanship Strict quality inspections

Workshop

Testing Equipment

Testing EquipmentHigh-quality raw materials, standard production processes, and strict quality inspections, Longyin Sealing strictly complies with the standard quality management system to produce sealed products.

Certificate

By seaDelivery time: about 25-45 days.

By seaDelivery time: about 25-45 days. By RailIf you are in Europe or Central Asia, railways are also a good choice.Delivery time: about 14-25 days.

By RailIf you are in Europe or Central Asia, railways are also a good choice.Delivery time: about 14-25 days. By AirFor some small and light products, air freight is our main choice.

By AirFor some small and light products, air freight is our main choice.Delivery time: about 5-8days.

Q1. What is the payment term?

Q1. What is the payment term?A: We accept a T/T 30% deposit and a 70% balance of a current bill of lading or a letter of credit. West Union, VISA is also

accepted.

Q2. What is the normal delivery time for product orders?

A: The average delivery time of the sample is 1-2 weeks. If the mold production is involved, the delivery cycle of the production

mold is 10 days, and the average production time after the sample is approved is 1-2 weeks.

Q3. What is your standard packaging?

A: All goods will be packed in PE bags and then packed in cartons and filled with trays. Special packaging methods are accepted

when needed, but charges may apply.

Q4. Which certificate do you have?

A1: Since 2012, we have passed ISO9001:2008: We have various rubber compounds certified by ROHS. 4 patents, still applying

for more patents.

Q5: How to check the quality of bulk orders?

A1: Our inspection procedures include, first inspection/patrol inspection/initial inspection/full inspection/shipment inspection.

A2: We provide quality certification to all customers before delivery, such as measurement reports, material data sheets, etc.

A3: We accept third party inspections such as SGS, TUV, INTERTEK, BV, etc.

Q6: How do I choose a raw compound for my application?

A: With years of experience in using a variety of materials, we can help you choose the material that best suits your needs,

keeping in mind the cost of materials.

Q7: Do you use any international standards for rubber products?

A: Yes, we mainly use the ASTM D2000 standard to define the quality of rubber materials according to ISO3302, ISO2768 and so on.

Q8: Can you provide materials of different colors?

A: Yes, we can produce custom Molded Rubber and silicone rubber products in different colors. Color codes are required when

ordering.

Q9: From which side can you produce which materials?

A: NBR, EPDM, silicone, FKM, NEOPRENE (CR), NR, IIR, SBR, ACM, AEM, fluorosilicon (FVMQ), FFKM, liquid silica gel, and the like.

Q10: What other services does LongYin seal offer?

A: We have an internal mold function that can be maintained and maintained; we have a cold chamber for elastomer storage to extend

product life. Contact us if you need more details on Bonded Washer. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Self-centering Bonded Gasket、Rubber Metal Bonded Sealing Washer. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Compound Gasket

Other Products

Hot Products

Customize Rubber Seal for Dynamic SealTs16949 High Quality with Factory Price Blue Hydraulic SealApproved Norsok M-710 Certificate FKM Aed O Ring for ValveBlack As568 Standard Quad Ring for Hydraulic CylinderChina Factory Supply Top Quality Rubber Oil SealRubber Viton Ring Va/Vs Seal for PumpFlat Gasket / Back-up Ring with FDA Confirmed for SealingFlexible Black NBR 70 Rubber Cord/Strip for SealingPTFE Spring Energized Seal for -196 Working ConditionSolid NBR Rubber Ball for Brake SystemFEP Encapsulated Black Viton O-Ring for SealingRubber Seals Rubber Gasket and Rubber PartsVarious Sizes of Rubber Oring Rubber Ring Spare PartsHigh Performance Industry Rubber Products and Rubber PartsFDA Silicone Rubber Seal Rubber Parts Rubber OringUL Approved NBR Custom Molded Rubber Products